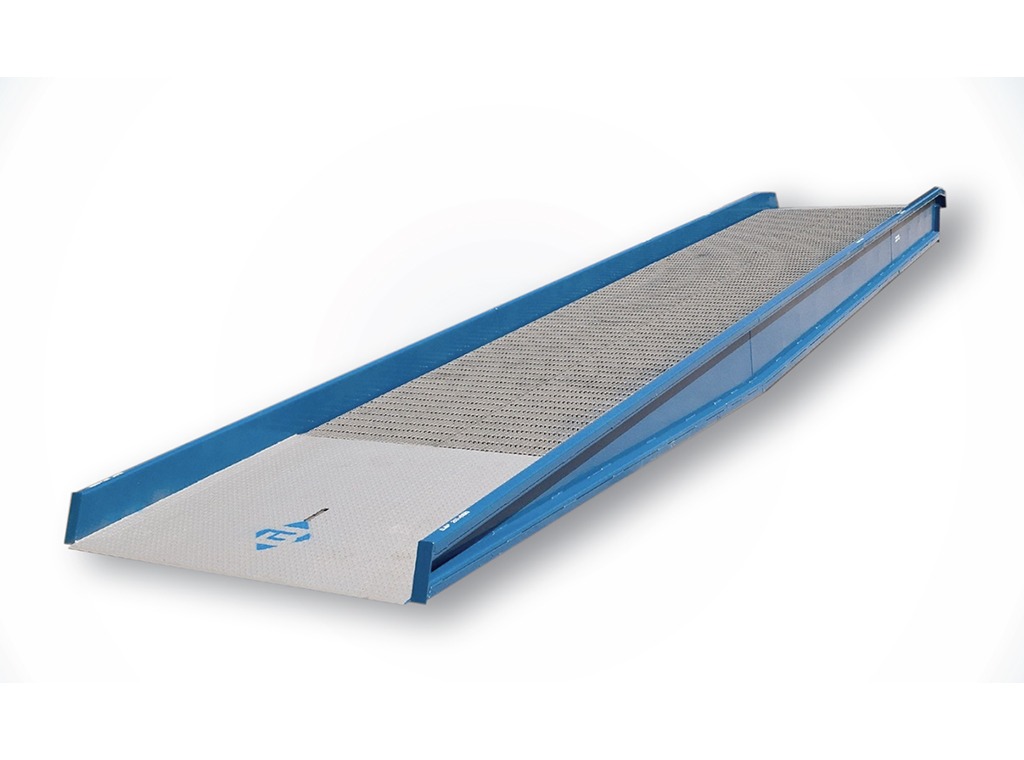

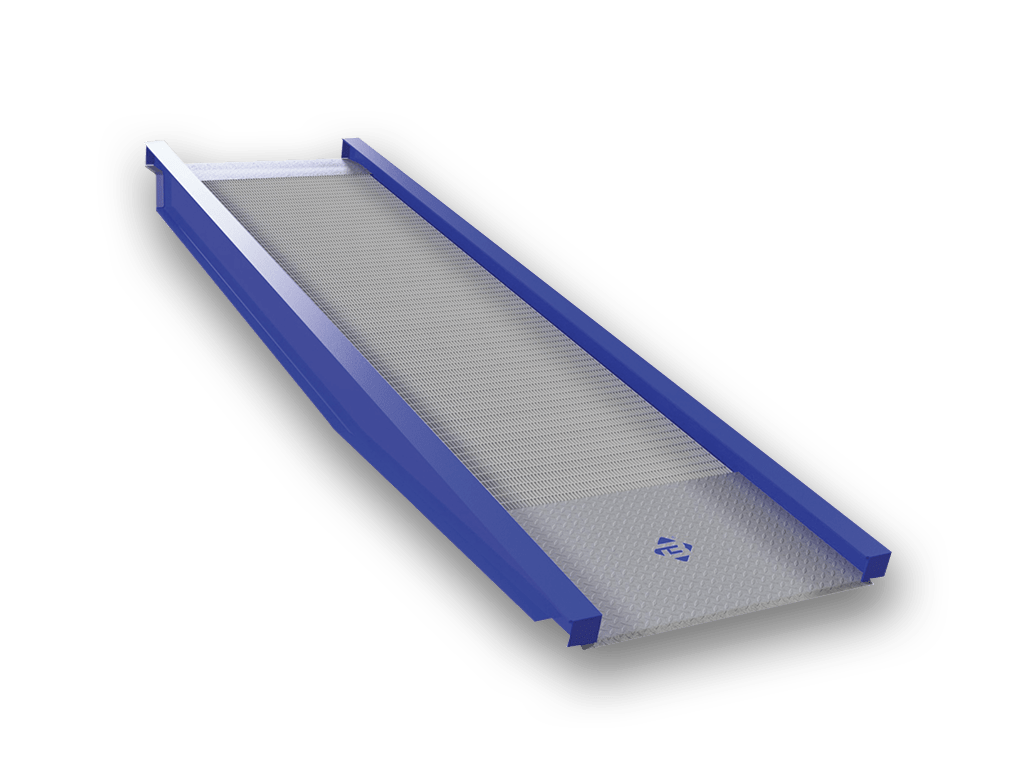

Stationary Steel Yard Ramps

Bluff’s stationary dock yard ramp provides a safe and efficient way for forklifts to move freight into and out of warehouse loading bays. The all-steel construction features a beveled diamond plate approach and serrated floor grating to provide exceptional traction while minimizing build-up of dirt, rain, snow and ice. Available in capacities from 16,000 to 60,000 Lbs.

Models

Stationary Steel Yard Ramps

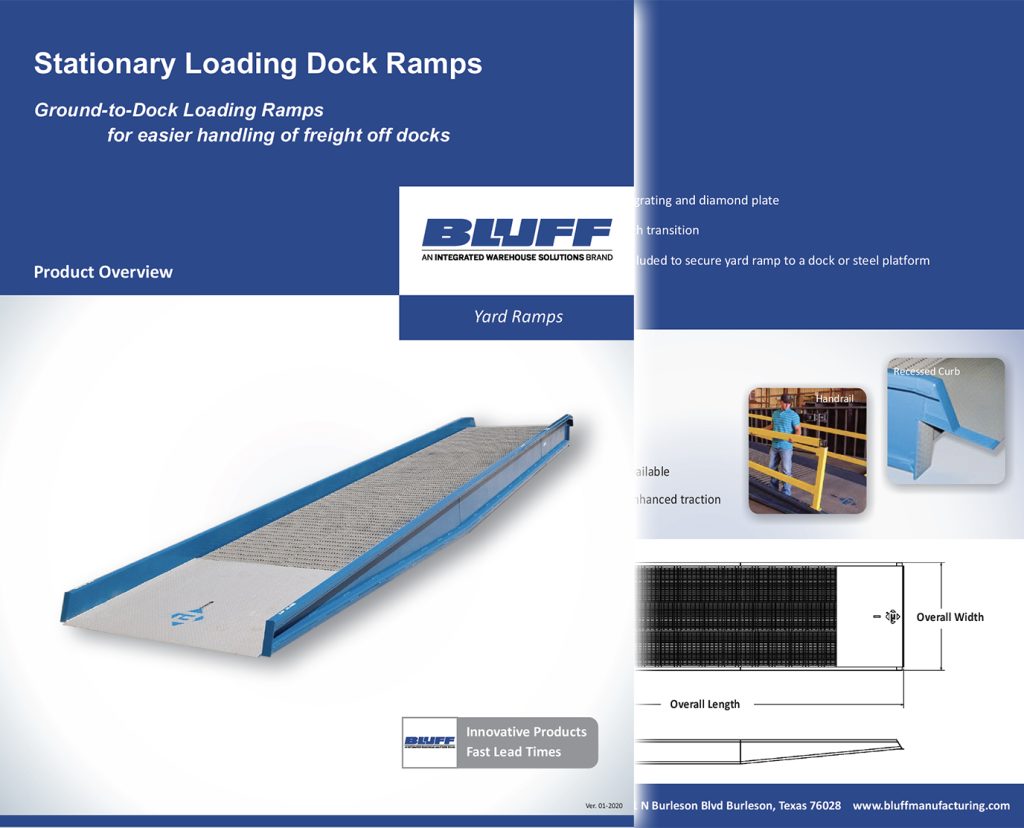

Ground-to-dock loading ramps for easier handling of freight off docks

High Capacity Stationary Steel Yard Ramp (Model SYSNU)

Ground-to-dock applications with loads up to 100k lbs.

Stationary Steel Yard Ramp

Overview

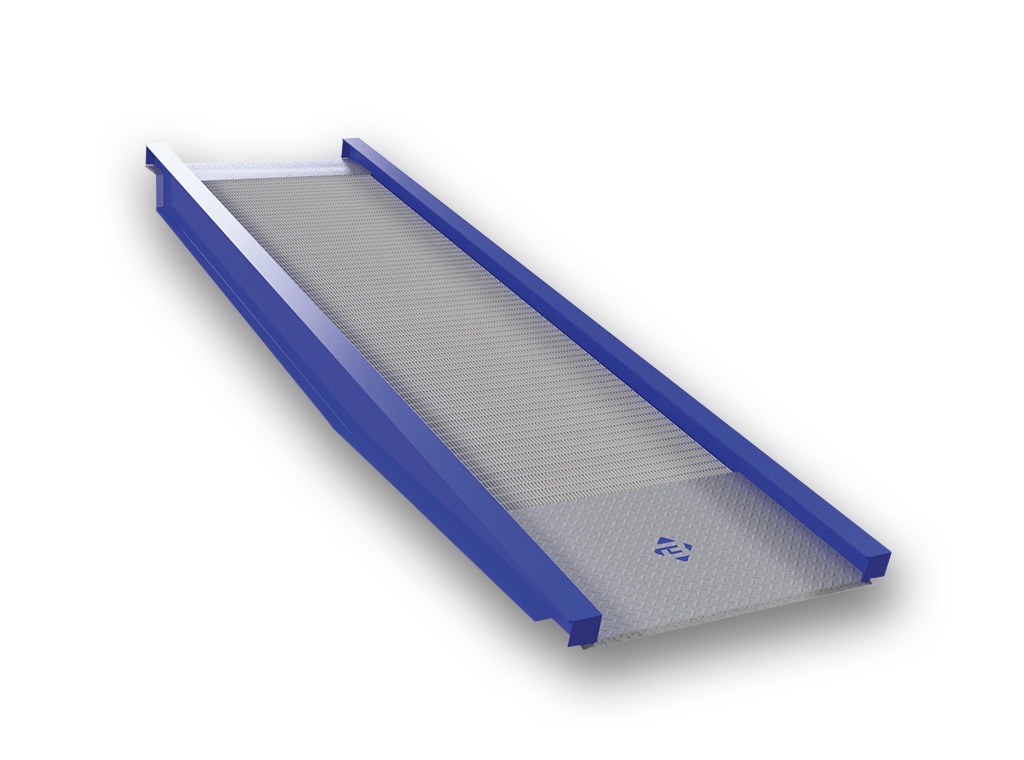

The Bluff loading dock ramp is set in place at concrete or portable steel loading dock when it is unloaded from the trailer. It is secured to the dock by chains and optional dock chain brackets. That’s it, your Bluff loading dock ramp is ready to use. Steel grating with the bearing bars oriented in the direction of travel gives maximum strength while the serrated top provides excellent traction while preventing build-up of snow, water, and other debris. Solid steel deck approach plates at both ends provide a smooth transition and maximum life for the ramp.

(CAUTION: Some competitor’s units use open grating at both ends… this allows the steering wheels of the forklift to twist the bearing bars causing failure).

Bluff’s Yard Ramps are the most copied design on the market. Our deep side members not only provide considerable run-off protection for forklifts, but also boast the strongest load member currently in use. If you’ve got a need for moving product from ground to dock via forklift or need to move a fleet of trucks into your building for any reason, a Bluff Ground-to-Dock Stationary Yard Ramp is the right choice.

Stationary Steel Yard Ramp

Features & Benefits

- All-Steel Welded Construction

- Capacities from 16,000 to 60,000 Lbs.

- 36’ Design Includes 6’ Level-Off

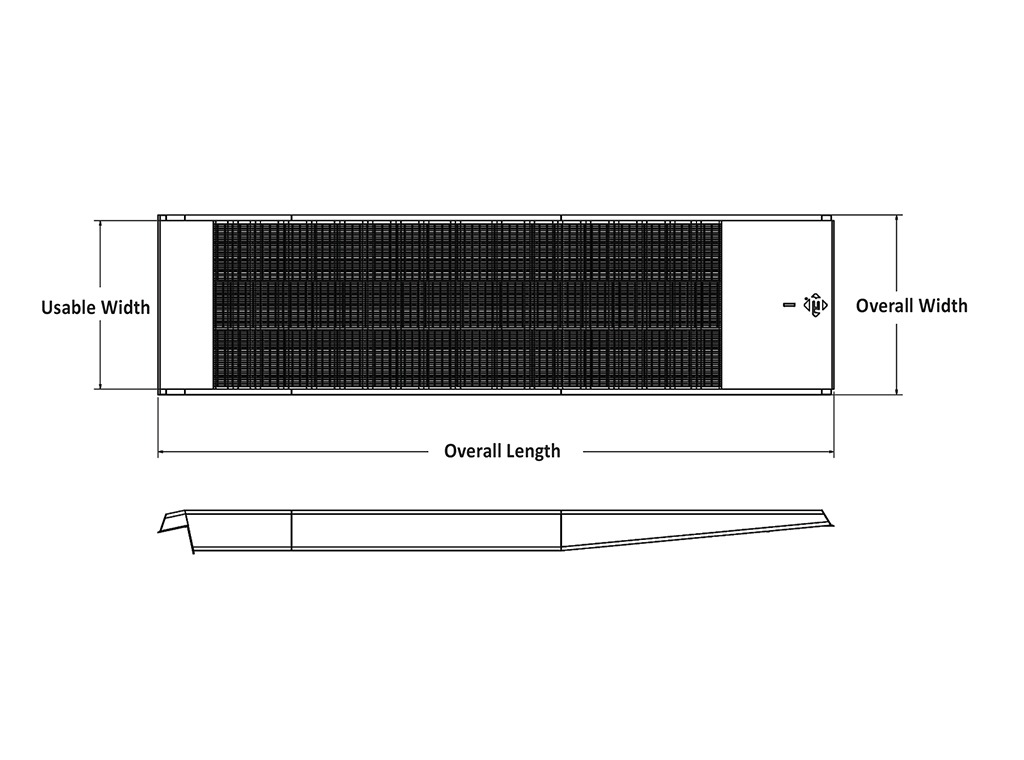

- Lengths from 20’ to 50’

- Widths from 70” to 130”

- Traction Provided by Serrated Steel Grating & Diamond Tread Plate

- Beveled Approach Provides a Smooth Transition

- Safety Chains & Chain Brackets Included to Secure Yard Ramp to a Dock or Steel Platform

Touch Up Paint for Yard Ramps:

- Rust-Oleum 249114 Gloss Deep Blue (Painter’s Touch line)

- Rust-Oleum 7786 Smoke Gray

Stationary Steel Yard Ramp

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Yard Ramp Worksheet

Download and fill out our Dock Board Worksheet to us help determine what solution best works for you.

Offloading Instructions

Stationary Steel Yard Ramp

Options & Accessories

- Recessed Curb

- Dock Extension

- Handrail

- Higher Capacities & Larger Widths Available

- Expanded Metal Added to Apron for Enhanced Traction

Coming Soon

(Model SYSNU)

Stationary Steel Yard Ramp

Overview

High-Capacity Yard Ramps from Bluff Manufacturing can be used for a variety of applications. Positioned in a farm field, high-capacity yard ramps can be positioned to transport perishable items efficiently from the field to a refrigerated trailer. Being able to load bailed hay onto a flatbed trailer in the field with the use of a yard ramp can save time and effort instead of needing to move bales to a different location and reloaded for transportation. At warehouses, the yard ramps can help to expand effectiveness of the buildings without permanent construction. If a company changes locations, the yard ramp can be moved with them.

(Model SYSNU)

Stationary Steel Yard Ramp

Features & Benefits

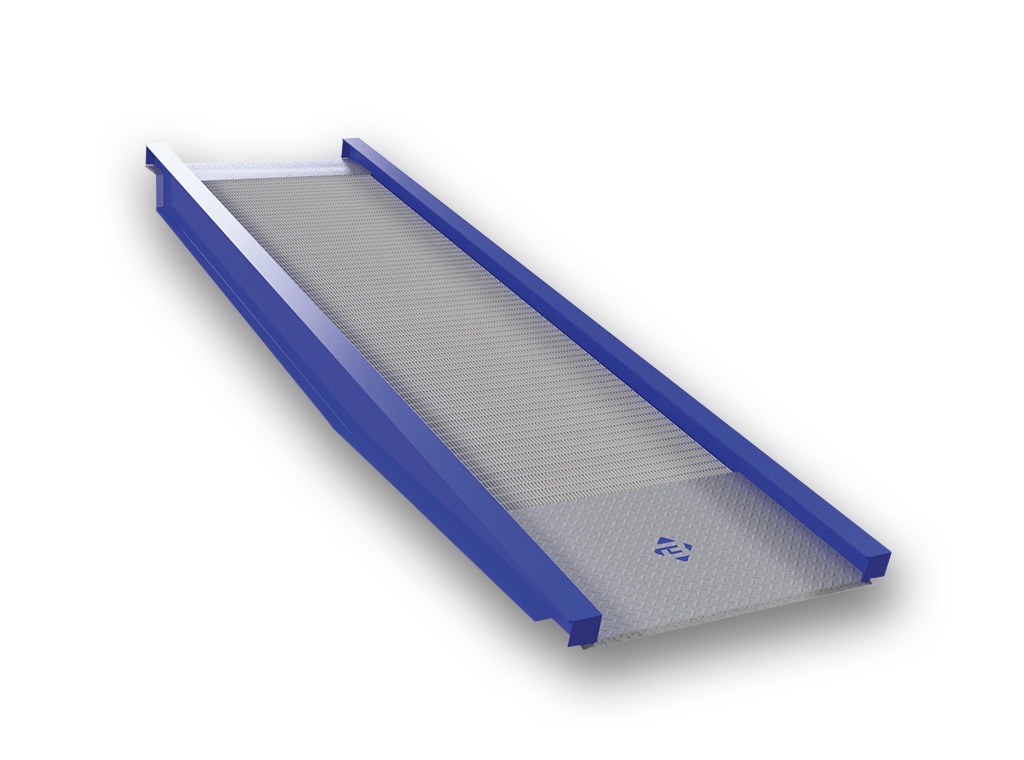

- All-Steel Welded Construction

- Capacities from 60,000 to 100,000 Lbs.

- Steel Serrated Grating

- Beveled Approach Provides a Smooth Transition

- Safety Chains Included to Secure Yard Ramp to a Dock or Trailer

- Uses Sturdy I-Beam Construction for Strength & Durability

- Widths Available Up to 144” (May be Shipped in Two Parts to Meet Transportation Regulations)

Touch Up Paint for Yard Ramps:

- Rust-Oleum 249114 Gloss Deep Blue (Painter’s Touch line)

- Rust-Oleum 7786 Smoke Gray

(Model SYSNU)

Stationary Steel Yard Ramp

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

Yard Ramp Worksheet

Download and fill out our Dock Board Worksheet to us help determine what solution best works for you.

Offloading Instructions

(Model SYSNU)

Stationary Steel Yard Ramp

Options & Accessories

- Military – Particularly Unloading Equipment Off Flatbeds

- Unique Situations Requiring Support for 60,000 + Lbs.

- Situations where a Heavy Tractor-Trailer Needs to Drive Through a Warehouse that is Not at Ground Level

- Scrap Yards – Loading Scrap Material into Containers that are Shipped Overseas for Recycling

- Commercial Real Estate, Rental Companies that Assist in the Move In/Out of Large Equipment to Warehouses

Coming Soon