Aluminum Ramps for Cylinders

Bluff’s AWL and AWC Aluminum Plates are specially designed for the safe transport and distribution of industrial, medical and specialty gases.

Unique to Bluff, the AWL and AWC plates are made of 3/8” aluminum diamond plate. These plates are light enough to be easily maneuvered by hand yet strong enough to accommodate capacities of up to 4,720 lbs.

Models

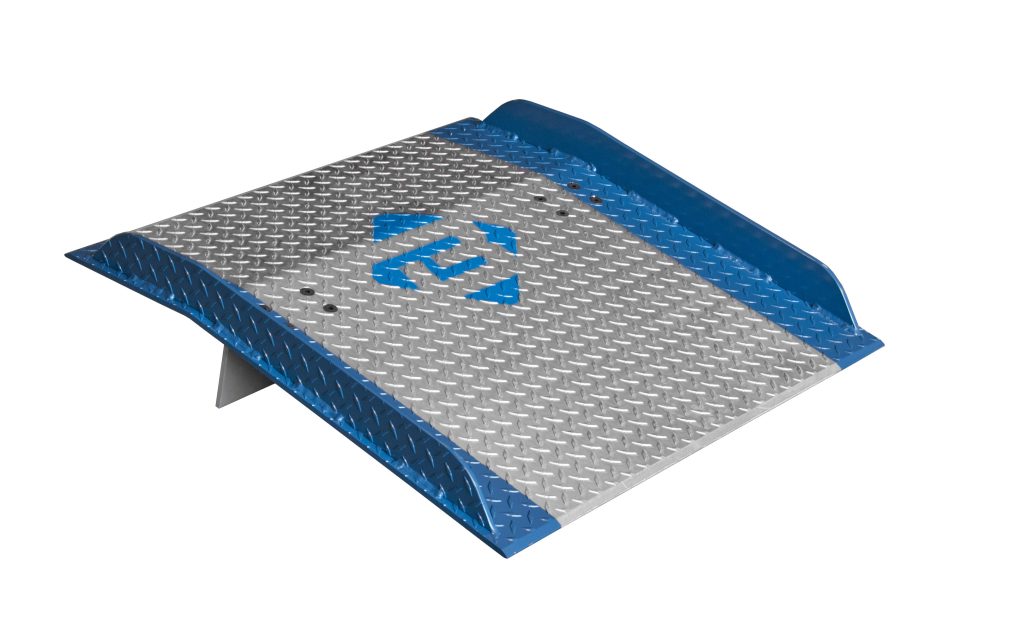

(Model AWL)

Gas Cylinder Aluminum Ramps

Overview

Bluff’s AWL Aluminum Plates are specially designed for the safe transport and distribution of industrial, medical and specialty gases. Unique to Bluff, the AWL plates are made of 3/8” aluminum diamond plate. These plates are light enough to be easily maneuvered by hand yet strong enough to accommodate capacities of up to 4,720 lbs.

In the gas cylinder distribution process, steel cylinder pallets are used to hold both filled and depleted cylinders. These pallets are typically three inches off the ground and present a logistical challenge in the manual removal of the cylinders. The heavy cylinders are individually and manually rolled off the pallet onto the dock or warehouse floor, without the use of a hand truck. Many distributors simply roll the cylinders off the three-inch height differential, ignoring the continuous potential for damage to the cylinder or dock/warehouse concrete floor with repeated cylinder impact. Additionally, there is a very real danger of losing control of the weighty cylinder during the drop resulting in potentially significant personnel injury and property damage.

When Bluff’s AWL plates are used as ramps for the gas cylinders, they prevent damage to the cylinder, while minimizing the risk of personnel injury and property damage. Manufactured and tested in compliance with ANSI standard MH30.2, our plates provides a smooth transition surface for manually maneuvering the cylinders in a fully controlled manner.

(Model AWL)

Gas Cylinder Aluminum Ramps

Features & Benefits

- Lightweight 3/8” Aluminum Diamond Plate

- Hand-Hole Cutouts for Easy Lifting & Maneuvering by Hand

- Capacities from 2,313 Lbs. to 4,730 Lbs.

- ANSI Code & Weight Capacity Stamped onto Back of Plate

- Standard Widths from 24” to 36”

- Standard Lengths from 24” to 36”

- Engineered to Match Pallet Height

- Welded Full Width Leg

(Model AWL)

Gas Cylinder Aluminum Ramps

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Gas Cylinder Pallet Ramp Plate – Model AWL & AWC.pdf

Freight Classes

Dock Board Worksheet

(Model AWL)

Gas Cylinder Aluminum Ramps

Options & Accessories

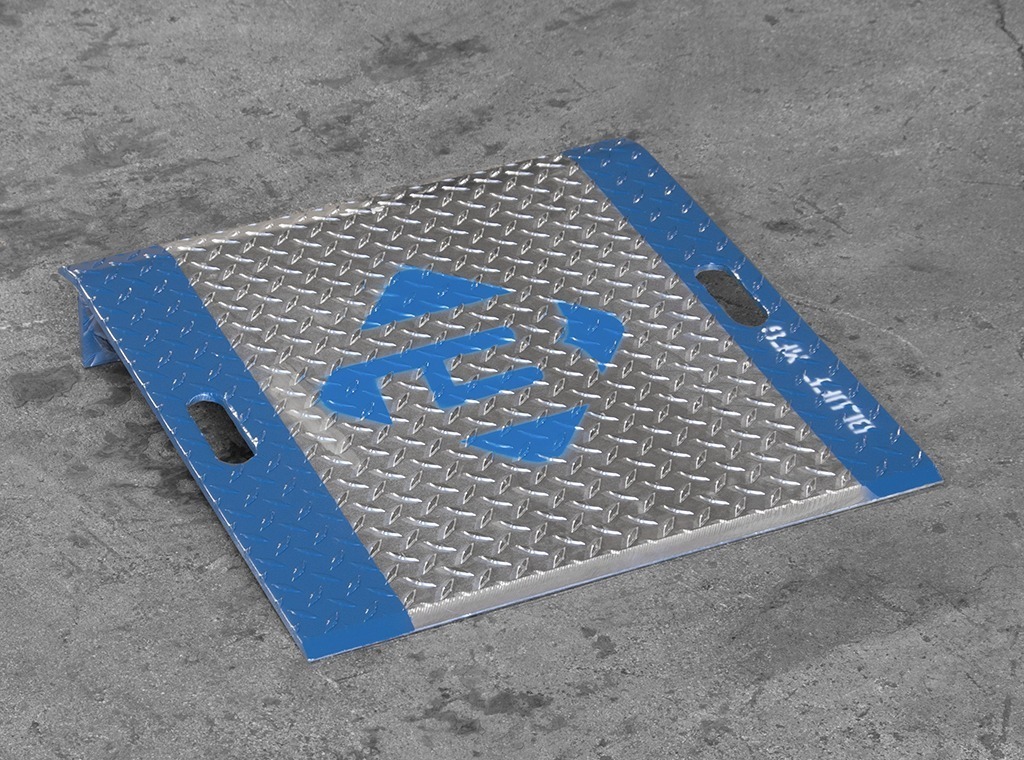

(Model AWC)

Gas Cylinder Aluminum Ramps

Overview

Bluff’s AWC Aluminum Plates are specially designed for the safe transport and distribution of industrial, medical and specialty gases. Unique to Bluff, the AWC plates are made of 3/8” aluminum diamond plate. These plates are light enough to be easily maneuvered by hand yet strong enough to accommodate capacities of up to 4,720 lbs.

In the gas cylinder distribution process, steel cylinder pallets are used to hold both filled and depleted cylinders. These pallets are typically three inches off the ground and present a logistical challenge in the manual removal of the cylinders. The heavy cylinders are individually and manually rolled off the pallet onto the dock or warehouse floor, without the use of a hand truck. Many distributors simply roll the cylinders off the three-inch height differential, ignoring the continuous potential for damage to the cylinder or dock/warehouse concrete floor with repeated cylinder impact. Additionally, there is a very real danger of losing control of the weighty cylinder during the drop resulting in potentially significant personnel injury and property damage.

When Bluff’s AWC plates are used as ramps for the gas cylinders, they prevent damage to the cylinder, while minimizing the risk of personnel injury and property damage. Manufactured and tested in compliance with ANSI standard MH30.2, our plates provides a smooth transition surface for manually maneuvering the cylinders in a fully controlled manner.

(Model AWC)

Gas Cylinder Aluminum Ramps

Features & Benefits

- Welded 4” Tall Run-Off Curbs on Both Sides for Added Control

- Lightweight 3/8” Aluminum Diamond Plate

- Hand-Hole Cutouts on Curbs Allow for Easy Lifting and Maneuvering by Hand

- Plates Larger than 48” have Two Hand Holes on Each Curb for Easier Handling

- Capacities are Size Specific

- ANSI Code & Weight Capacity Stamped onto Back of Plate

- Standard Widths from 30” to 48”

- Lengths from 30” to 60”

(Model AWC)

Gas Cylinder Aluminum Ramps

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Gas Cylinder Pallet Ramp Plate – Model AWL & AWC.pdf

Freight Classes

Dock Board Worksheet

(Model AWC)

Gas Cylinder Aluminum Ramps

Options & Accessories

Dock Equipment