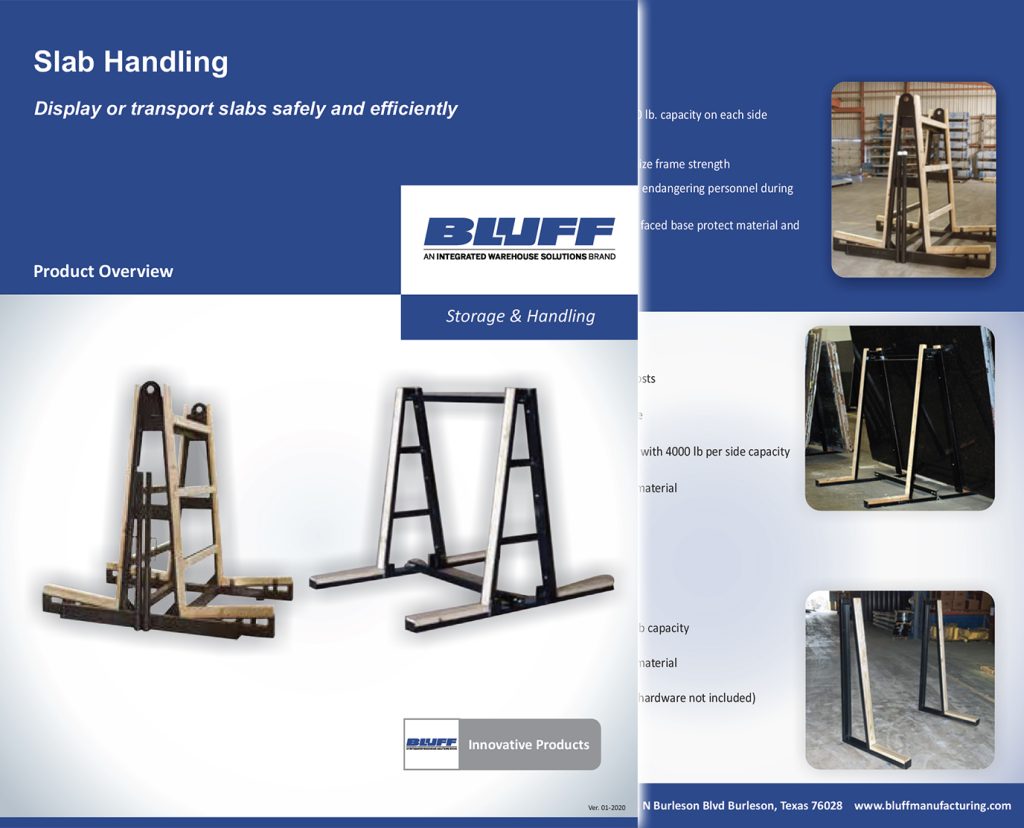

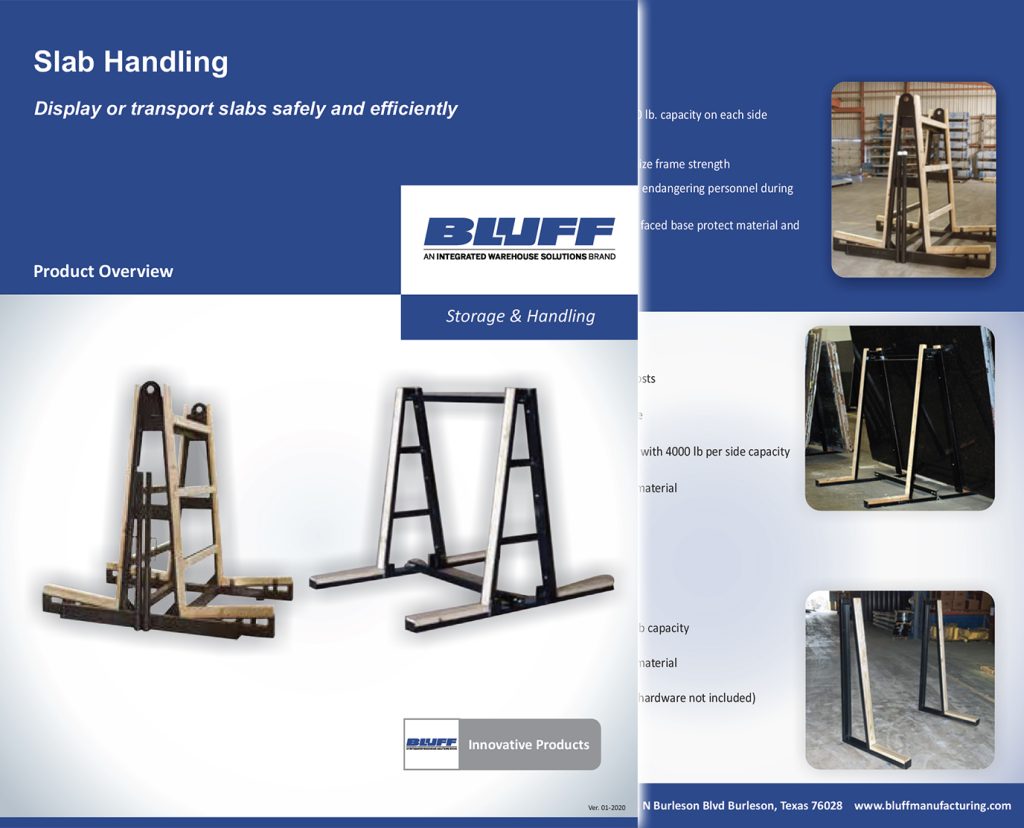

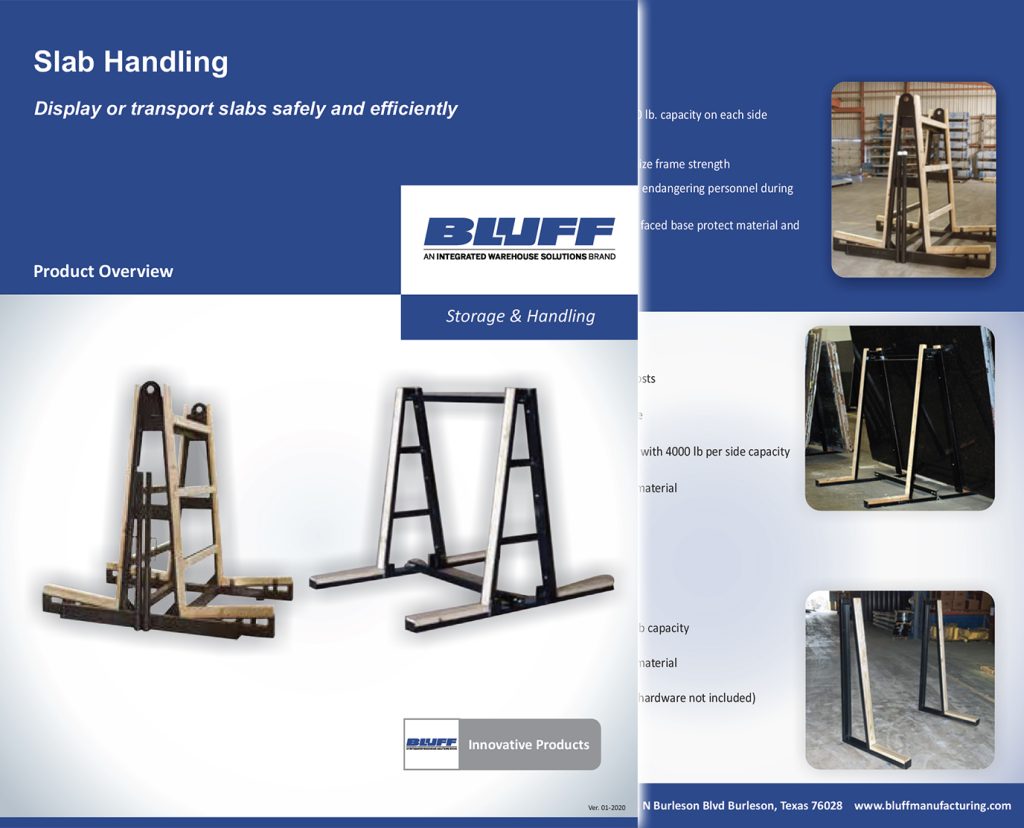

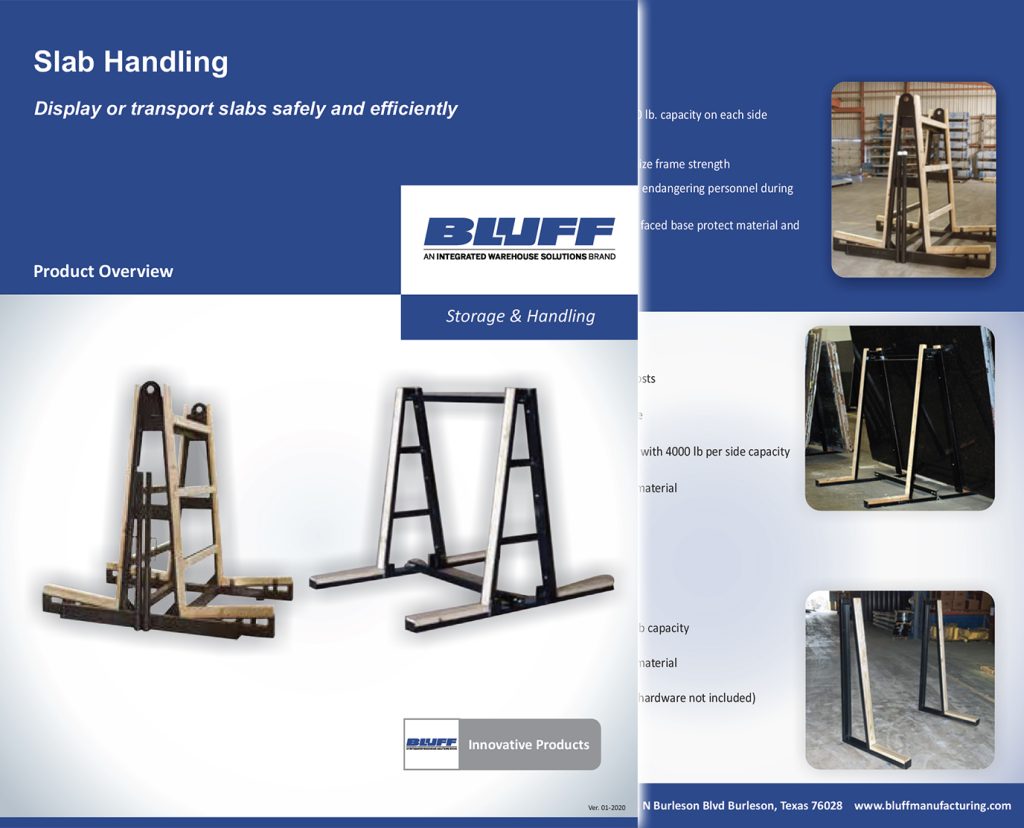

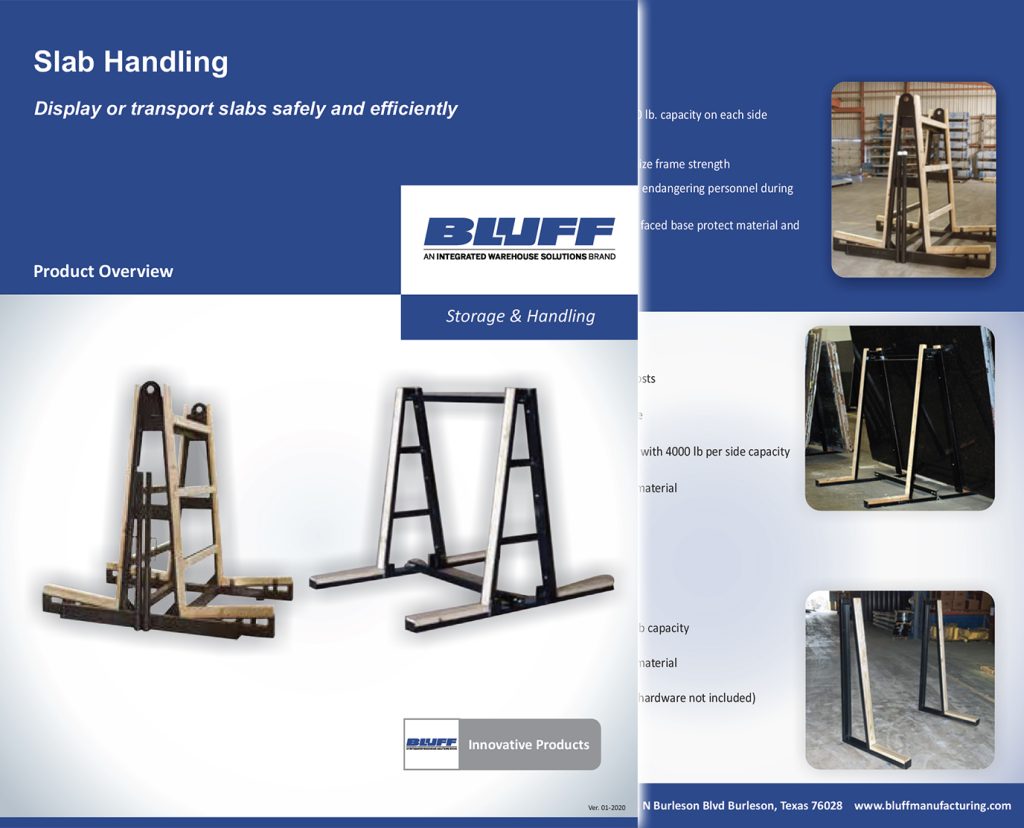

Slab Handling Equipment

Natural stone and granite slabs are heavy and costly materials that require specifically designed equipment to safely handle, transport, display and store.

Bluff has developed a series innovative products for slab handling that increases safety and security and enhances the display of slab products.

Models

Showroom Slab Display Rack

Helps show the specific grains & textures while safely securing the product

A-Frame Slab Transport Rack

Slab Handling Equipment

Overview

Stone slab handling rack uniquely designed for use in transport as well as showroom display. Extreme heavy-duty construction provides unmatched durability. Innovative safety features furnish secondary bracing and support system to safeguard your personnel and to protect your materials.

Extreme heavy-duty construction provides unmatched durability. Innovative safety features furnish secondary bracing and support system to safeguard your personnel and to protect your materials.

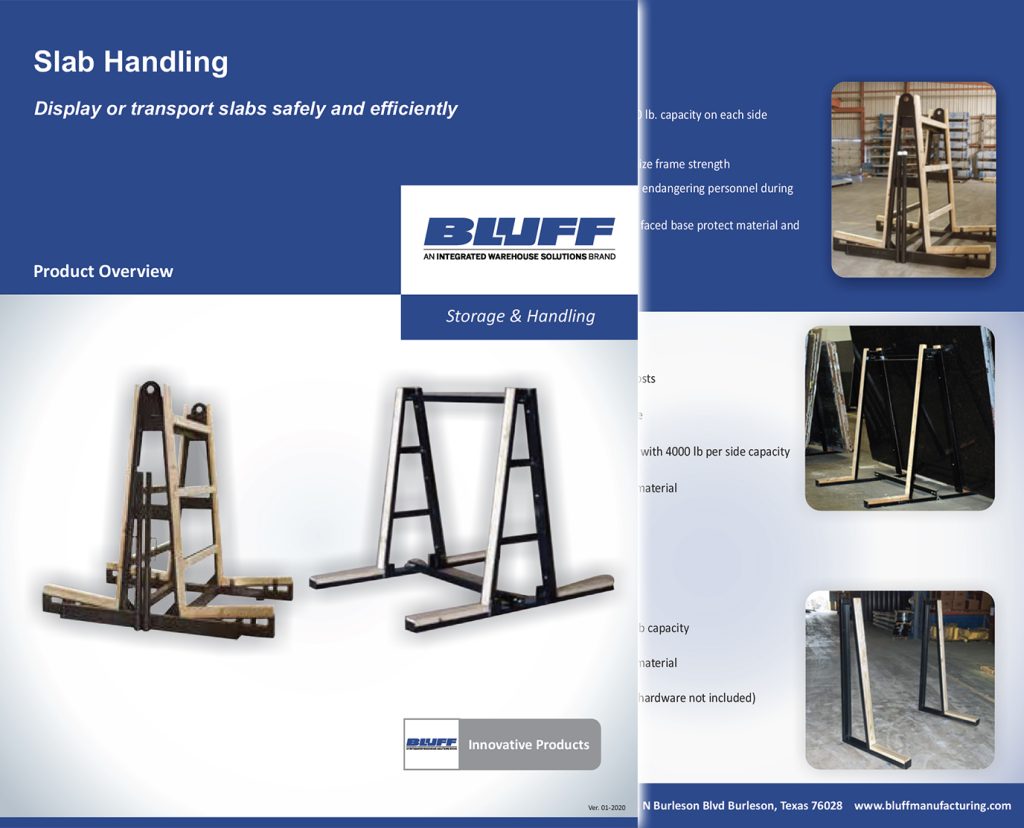

A-Frame Slab Transport Rack

Slab Handling Equipment

Features & Benefits

- Dimensions: 72” x 95” x 92” with 10,000 Lb. Capacity on Each Side

- All Welded Steel Frame Manufactured from A-36/50 Structural Steel Pipe & Structural Channel Steel–No Bolting

- Three Steel Crossbars Per Side to Maximize Frame Strength

- 5’ Vertical Handled Steel Pipe Inserted into Integrated Nominal 6” Safety Stop Pockets Provides Secure Positioning of Slabs for Delivery Accessibility

- Safety Stops Prevent Shifting Loads from Endangering Personnel during Loading & Unloading

- Timber-Faced Steel Structure & 4” x 4” Wood Base Stud Along Angled Steel Base Protect Material & Increase Stability

- Welded Anchor Plates Supplied for Delivery Truck Mounting

- Frames can be Inspected Upon Request by a Certified Welding Inspector & Uniquely Marked with ID Code for Tracking

- Custom Sizes & Designs Available

A-Frame Slab Transport Rack

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

Freight Classes.pdf

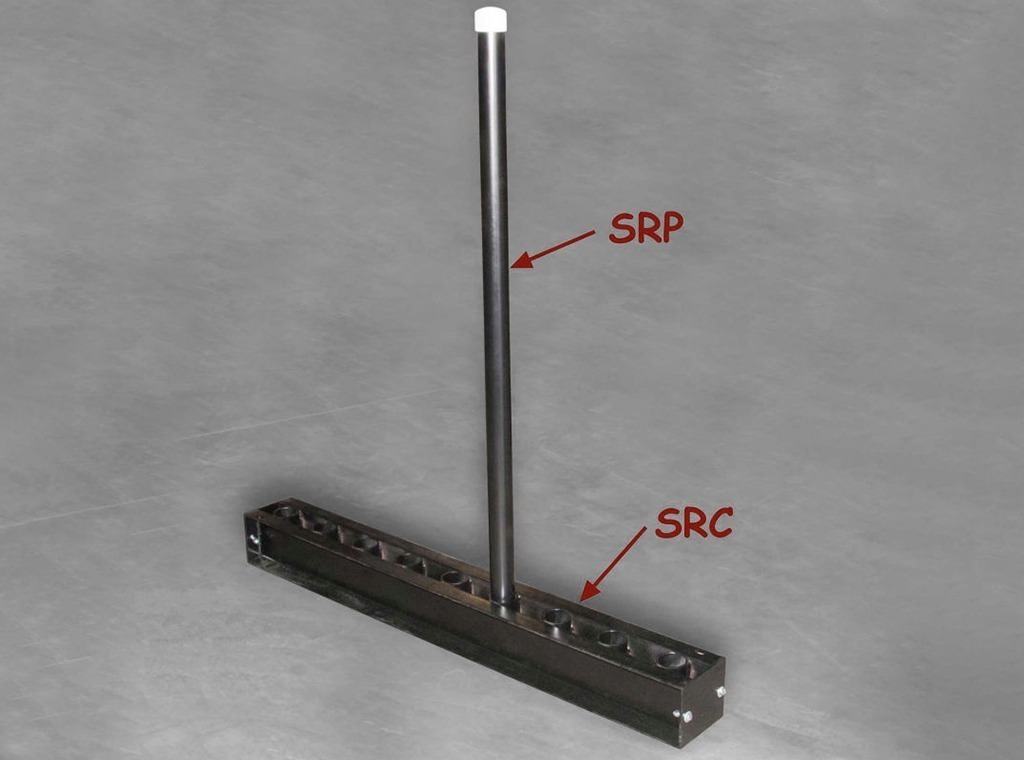

Slab Transport Rack (Retro Safety Kit)

Slab Handling Equipment

Options & Accessories

Retro Safety Kit allows for the addition of integrated slab safety supports into existing A-Frame slab transport racks. The welding of safety stop pockets along base of one end of the frame combined with the insertion of a 60” vertical handled steel pipe into these pockets provides a secondary bracing element for slab accessibility during delivery.

- All Welded Pipe & Structural Channel Steel – No Bolting

- One (1) Center Storage Pocket & Three (3) Nominal 6” Safety Positioning Pockets are Located Each Side of One End of the Frame

- Included are Two 60” Posts with Handle

- Each Painted Post is Handled & Includes a PVC Plastic Cap for Protecting Slab Finish

- Kit can be Bolted to Truck Bed or Welded to the Base of the Existing Transport A-Frame

| Model Number | Weight |

|---|---|

| AFRAME-SRC5 | 92.00 |

| AFRAME-SRC6 | 112.00 |

| AFRAME-SRP5 | 20.00 |

| AFRAME-SRP6 | 22.00 |

| AFRAMEPOST5H | 21.00 |

| AFRAMESTD | 200.00 |

| AFRAMETRUCK | 838.00 |

| AFRAMEWALLRACK | 185.00 |

Slab Rack Floor Display Unit

Slab Handling Equipment

Overview

Display A-Frame set for use in showroom applications. Two all-welded A-Frames are securely joined with two structural angle cross members for a solid display unit. Enhances the security of your slabs in a public showroom.

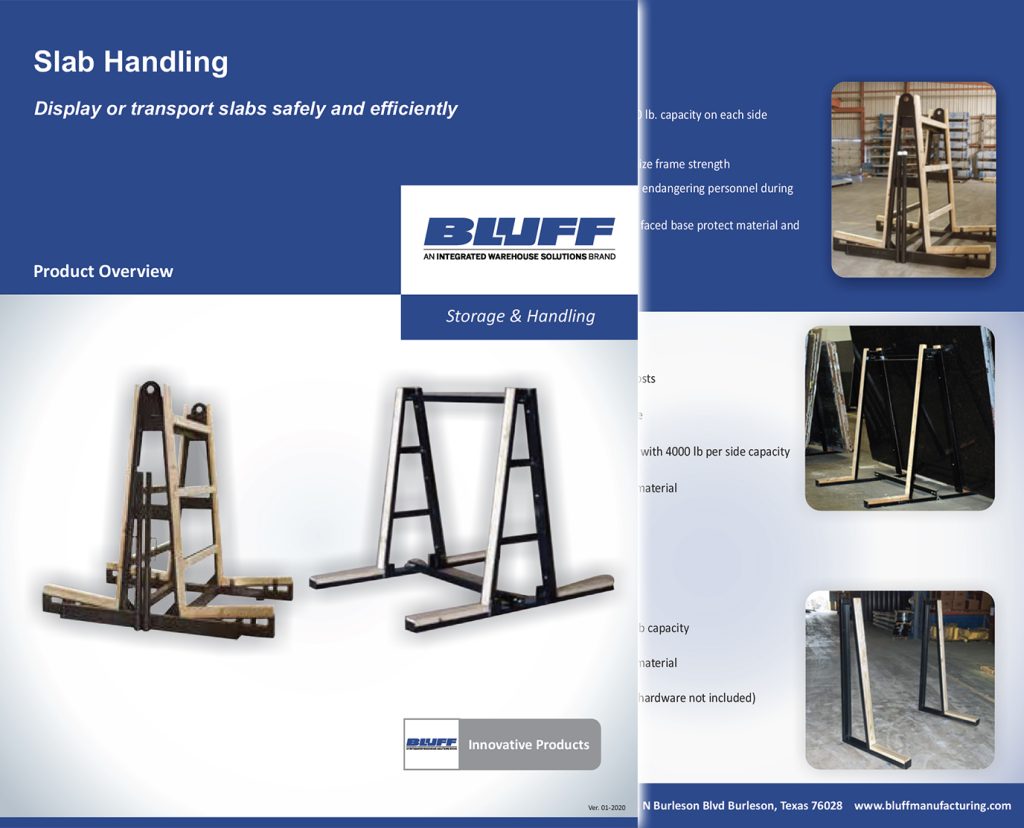

Slab Rack Floor Display Unit

Slab Handling Equipment

Features & Benefits

- Includes Two (2) A-Frames & Two (2) Cross Members; Shipped KD & Easily Assembled Using Furnished Hardware

- Constructed of Specially Designed Cold Formed Sections of 50,000 PSI Steel

- Assembled Dimensions: 60” X 60” X 60” with 4000 Lb. Per Side Capacity

- Wooded Faced Uprights & Base Protect Material

- Dimensions: 5’ D x 5’ W x 5’ H

- Weight: 245 Lbs.

- Ships Knocked Down for Lower Freight Costs

- Not Intended for Transport

Slab Rack Floor Display Unit

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

Slab Rack Floor Display Unit

Slab Handling Equipment

Options & Accessories

Retro Safety Kit allows for the addition of integrated slab safety supports into existing A-Frame slab transport racks. The welding of safety stop pockets along base of one end of the frame combined with the insertion of a 60” vertical handled steel pipe into these pockets provides a secondary bracing element for slab accessibility during delivery.

- All Welded Pipe & Structural Channel Steel – No Bolting

- One (1) Center Storage Pocket & Three (3) Nominal 6” Safety Positioning Pockets are Located Each Side of One End of the Frame

- Included are Two 60” Posts with Handle

- Each Painted Post is Handled & Includes a PVC Plastic Cap for Protecting Slab Finish

- Kit can be Bolted to Truck Bed or Welded to the Base of the Existing Transport A-Frame

Slab Rack Wall Display Rack

Slab Handling Equipment

Overview

For use in showroom applications, the Single-Sided Display Rack sits flush to a wall providing a secure platform for slab presentation. Each set contains two vertical frames which, when mounted to a wall, provides a single-sided display rack to support one piece of slab. This enhances the security of your slabs in a public showroom.

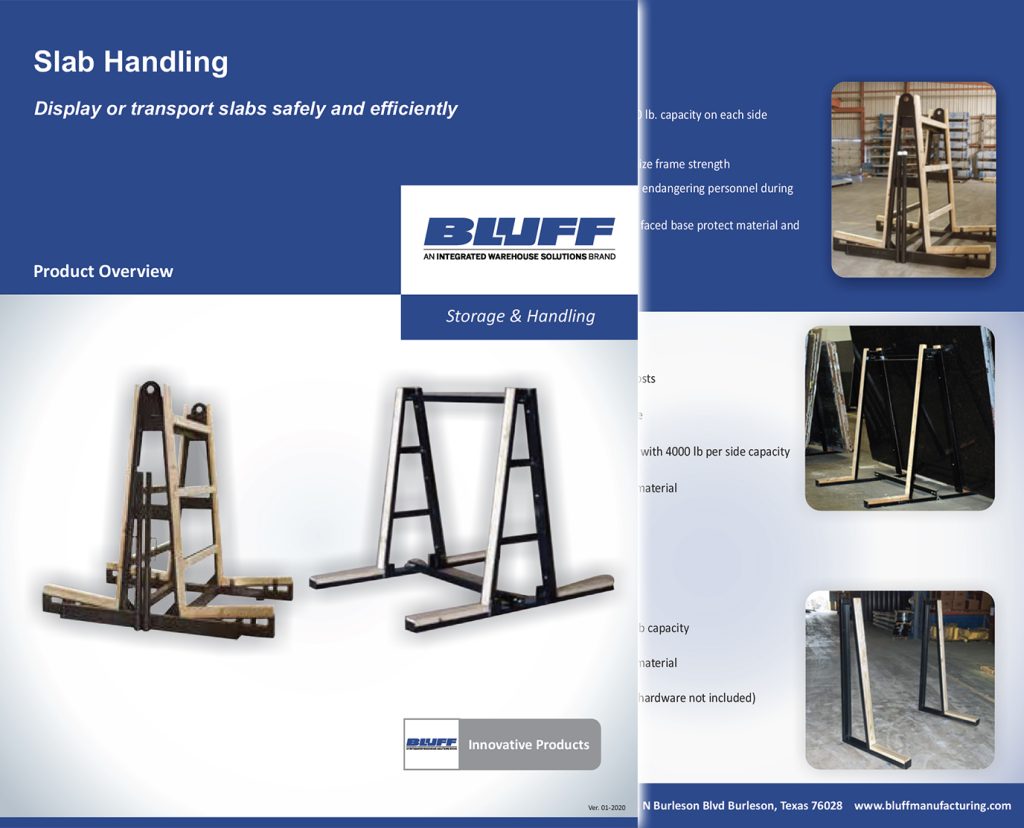

Slab Rack Wall Display Rack

Slab Handling Equipment

Features & Benefits

- Dimensions: 60” X 36” X 60” with 4000 Lb. Capacity

- Wood Faced Uprights & Base Protect Material

- Mount to Wall Through Provided Holes (Hardware not Included)

- Weight: 185 Lbs. Per Set

- Includes 2 Vertical Frames; Shipped KD & Easily Assembled using Furnished Hardware

- Constructed of Specially Designed Cold Formed Sections of 50,000 PSI Steel

- Not Intended for Transport

Slab Rack Wall Display Rack

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

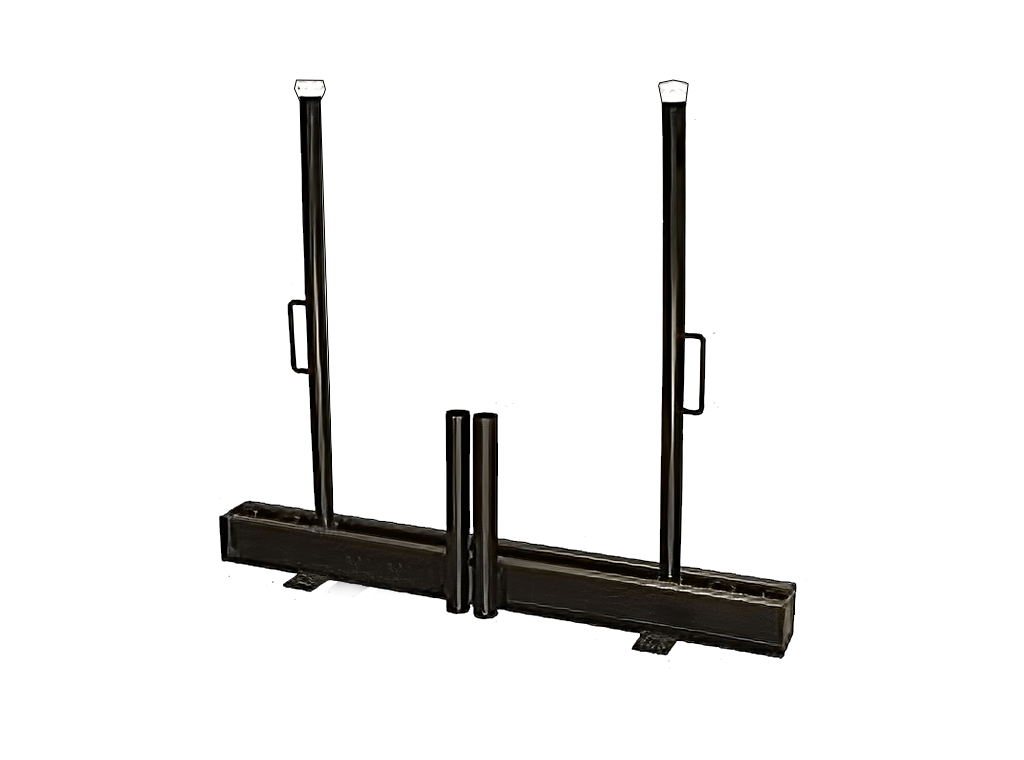

A-Frame Slab Rack Channel

Slab Handling Equipment

Overview

Paired 5’ slab rack channels with either 5” or 6” deep pockets for safety post insertion. All welded channel manufactured from structural steel, designed for use in storage and showroom display. Heavy duty construction provides unmatched durability. Made in 5’ sections for shipping convenience. Sections can be bolted or connected for longer runs; channels punched for floor anchoring. Slab Rack Posts are sold separately (see description below).

A-Frame slab rack channel

Slab Handling Equipment

Features & Benefits

- 6” Deep Pockets X 120” Long

- Dimensions Options of 5’ X 5” or 5’ X 6”

- All Welded Steel Frame Manufactured from 2 ½” Schedule 40 Steel Pipe & Structural Channel Steel – No Bolting

- Posts Sold Separately

- Custom Lengths Available

A-Frame Slab Rack Channel

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

A-Frame Slab Rack Post

Slab Handling Equipment

Overview

Slab rack posts are constructed of 2” schedule 40 painted steel pipe. Posts are 5’ high and are used for insertion into pockets of 5” or 6” channel slab racks. The posts are secured into variable pockets of slab racks for slab storage and/or display. All posts are painted and include a PVC cap for personnel safety and product protection.

A-Frame Slab Rack Post

Slab Handling Equipment

Features & Benefits

- Height of 5 Feet

- 2 ½ X 2 ½ X 3/16” Structural Steel Tubing

- Vinyl Protective Cap

A-Frame Slab Rack Post

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

Slab Rack Post w/Handle

Slab Handling Equipment

Overview

This 5-foot slab rack post comes with a welded handle for ease of retrieval and insertion into pockets of slab racks. Post is secured into pockets of slab racks for slab storage, display or transport. All posts are painted and include a PVC cap for personnel safety and product protection. Handled Posts are for use with Bluff’s A-Frame Slab Transport Racks.

Slab Rack Post w/Handle

Slab Handling Equipment

Features & Benefits

- Height of 5 Feet

- Welded Handle

- 2” Schedule 40 Painted Steel Pipe

- PVC Protective Cap

Slab Rack Post w/Handle

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

Showroom Slab Display Rack

Slab Handling Equipment

Overview

Bluff Manufacturing’s Showcase Display Rack is a unique way to showcase high value slab products in the showroom. Our Showcase Display Rack helps show the specific grains and textures while safely securing the product. Internal lighting can be added to show additional product details in translucent materials.

Showroom Slab Display Rack

Slab Handling Equipment

Features & Benefits

- Showcases & Fully Encloses up to 2 Standard Slabs – Double Sided

- Safely Secures Slabs

- Made or Fully Welded Steel with Removable Top

- Powder Coated Finish (Standard: Black)

- Easy to Open & Install Product

- Manufactured to Accept Internal Lighting (Not Supplied)

- Designed to Hold Fragile Slab Materials

- Allows for Internal Lighting

Showroom Slab Display Rack

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.

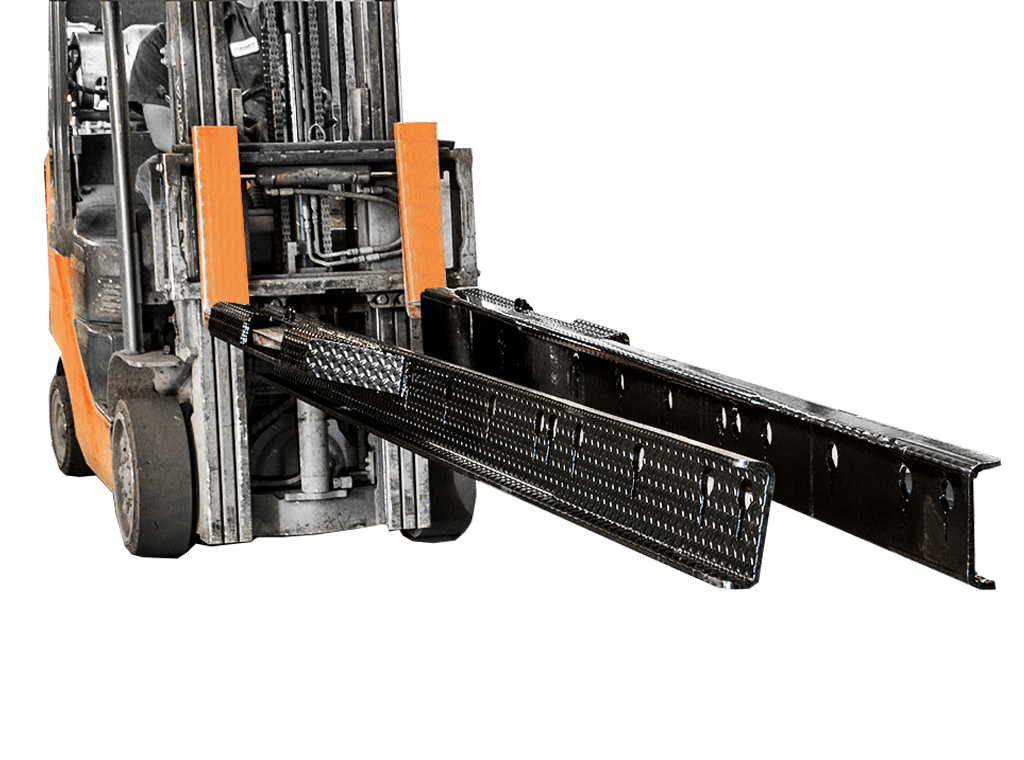

Slab Handling Fork Attachments

Slab Handling Equipment

Overview

Bluff Manufacturing’s Slab Handling Fork Extensions extend the reach of your existing forklift tines to move and handle heavy slab products like Marble and Granite. Our Fork Extensions make moving these products safer and protect the slabs in transit. Bluff Slab Handling Fork Extensions fit standard Forklift Tines and can be customized to fit unique styles. They are removable from the forklift and use chains to secure the slabs. They are made of heavy-duty steel that has been welded and customized to your specific forklift. Bluff Slab Handling Fork Extensions are manufactured to match existing forklift capacity.

Slab Handling Fork Attachments

Slab Handling Equipment

Features & Benefits

- Customized to Forklift Capacity & Fork Size

- Uses 5/16” Lifting Chain to Cradle the Slab (Not Included)

- Designed for Lifting & Moving Granite, Marble & Other Solid Slab Products

- Fully Welded – Steel Construction

- Powder Coated Finish (Standard: Black)

Slab Handling Fork Attachments

Slab Handling Equipment

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Freight Classes

Bluff Manufacturing strives to give the best possible customer service. Download our freight classes for shipping.