My company has been going thru a year long initative on training. We have always trained in our functional areas and even did cross training inside of our departments. We are betting that we can become a better company if we allow all employees the opportunity to learn more about all areas. The more we each understand….the more perspective we have….the better we function. Having said that, a large portion of the reason for this blog is to train. First ourselves, then our dealers and their salespeople and then the public at large about our industry and how it affects each of us. So lets start with a basic knowledge block.

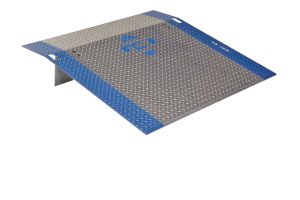

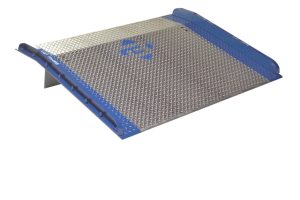

A dock plate is just that. It is a plate made from either aluminum or steel that has no other structure that adds to its ability to carry weight. It is made for handtrucks and other non powered equipment. Each size is assigned a capacity for that specific size driven by span, width and material thickness. They will have legs (in most cases) that lock the plate into place for use and some accomodation for handling. Either hand cutouts or handles.

A dock board on the other hand is the plate with other structure that adds to the capacity. This is in the form of curbs and sometimes box structure on the underside. There are various methods of fixing the board in place. They include lock legs, drop pins and positioning rings to name a few. The capacities are a function of the plate thickness and the supporting structure and typically range from 10K to 90K.

A rail board is a board with a large supporting understructure that serves to keep the board in place while adding to the capacity. It will use lock rings to take up space and insure a snug fit. Each rail board is fabricated for a specific dock/rail car application.