Container Ramps

The Bluff Container Ramp is the perfect answer to your need to load and unload shipping containers. It allows you to safely navigate the transition from ground to the bed of the container. The result is a safe, sturdy ramp locked firmly to the container. You can now load and unload your container safely – AND QUICKLY!

(Model CR)

Container Ramps

Overview

The Bluff Shipping Container Ramp is used to load and unload cargo from shipping containers with a forklift. It allows you to safely navigate the transition from ground to the bed of the shipping container.

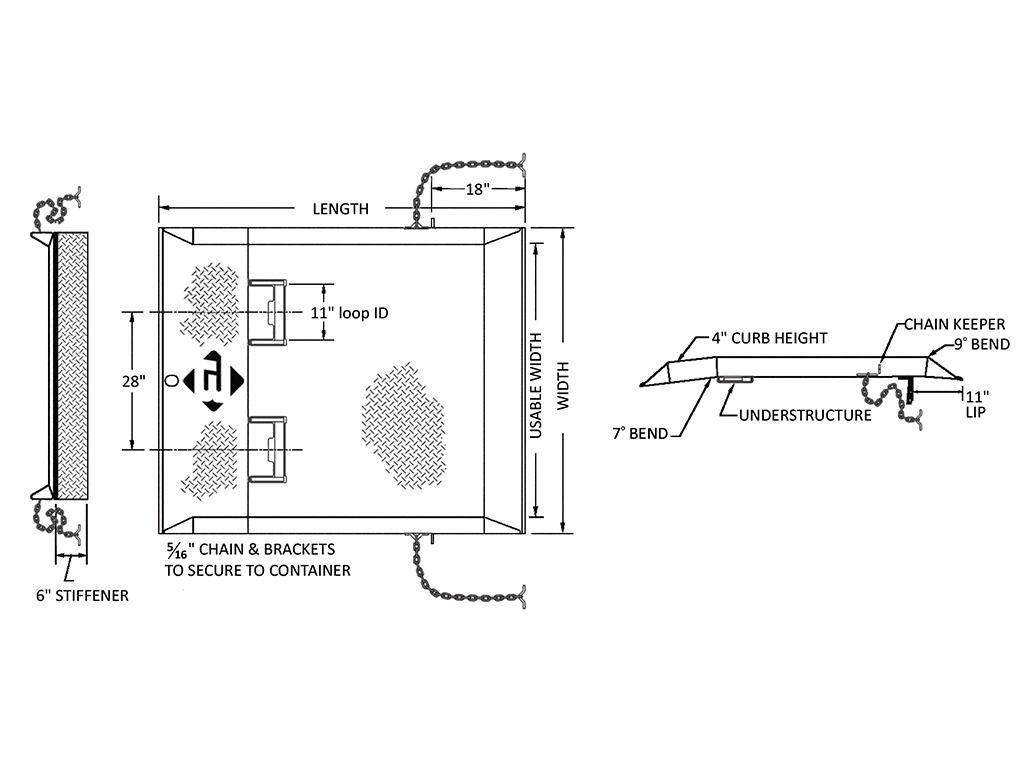

Bluff Container Ramps are built tough to withstand heavy use. They are built to last. These Shipping Container Ramps feature a full width stiffener to provide strength and to bump up against the container. Locking chains with a specially designed keeper allow you to easily lock it into the holes in the container. After the keepers are in place, taking up the slack in the chain is simple and quick with the sturdy grab notch bracket welded to the sides of the Container Ramp. The result is a safe, sturdy loading ramp locked firmly to the shipping container. You can now load and unload your container safely – AND QUICKLY! Standard shipping Container Ramps are available in 15K, 20K, 25K, and 30K capacities. Other sizes available.

Manufactured and tested in compliance with ANSI Standard MH30.2.

Capacities from 15,000 to 40,000 Lbs.

(Model CR)

Container Ramps

Features & Benefits

- All-Steel Welded Construction

- Standard Capacities from 15,000 to 40,000 Lbs.

- Fold Down Lift Loops

- Rugged, Efficient, Safe, Economical

- Full Width Stiffener Bumps Up Against the Container for Stability

- Locking Chains Included to Lock Ramp into Place

- 4” Tall Curbs on Each Side Serve as Runoff Protection

- Sturdy Grab Notch Bracket Welded to the Sides of the Ramp

- Widths Starting at 60”

- OSHA 1910.26 Compliant

(Model CR)

Container Ramps

Literature

Provides a detailed overview of the performance, operation, & other important characteristics.

Unloading Instructions

Provides detailed information & instructions used to safely unload the product.

Freight Classes

(Model CR)

Container Ramps

Options & Accessories

- Higher Capacities & Custom Designs Available

- 14” Lip for Refrigerated Containers

- Speedy Board Cutouts

Coming Soon

| Model Number | Capacity (lbs) | Width (in) | Length (in) | Weight (lbs) |

|---|---|---|---|---|

| 15CR6048 | 15000 | 60 | 48 | 489.00 |

| 15CR6060 | 15000 | 60 | 60 | 573.00 |

| 15CR6072 | 15000 | 60 | 72 | 658.00 |

| 15CR6084 | 15000 | 60 | 84 | 750.00 |

| 15CR6096 | 15000 | 60 | 96 | 827.00 |

| 15CR7248 | 15000 | 72 | 48 | 565.00 |

| 15CR7260 | 15000 | 72 | 60 | 663.00 |

| 15CR7272 | 15000 | 72 | 72 | 761.00 |

| 15CR7278 | 15000 | 72 | 78 | 811.00 |

| 15CR7284 | 15000 | 72 | 84 | 860.00 |

| 15CR7296 | 15000 | 72 | 96 | 958.00 |

| 15CR8448 | 15000 | 84 | 48 | 641.00 |

| 15CR8460 | 15000 | 84 | 60 | 753.00 |

| 15CR8472 | 15000 | 84 | 72 | 865.00 |

| 15CR8478 | 15000 | 84 | 78 | 937.00 |

| 15CR8496 | 15000 | 84 | 96 | 1037.00 |

| 20CR6048 | 20000 | 60 | 48 | 552.00 |

| 20CR6060 | 20000 | 60 | 60 | 649.00 |

| 20CR6084 | 20000 | 60 | 84 | 798.00 |

| 20CR6096 | 20000 | 60 | 96 | 818.00 |

| 20CR7248 | 20000 | 72 | 48 | 639.00 |

| 20CR7260 | 20000 | 72 | 60 | 681.00 |

| 20CR7272 | 20000 | 72 | 72 | 833.00 |

| 20CR7284 | 20000 | 72 | 84 | 980.00 |

| 20CR7296 | 20000 | 72 | 96 | 1094.00 |